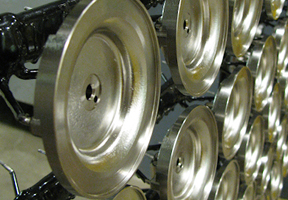

General Details and Specification of electroless nickel finishes

Similar to stainless steel in color. Plates uniformly in recesses and cavities (does not build up on edges). Corrosion resistance is good for coatings over .001" thickness. Electroless nickel is used extensively in salvage of mismachined parts. Also, for inside dimensions and irregular shapes (where assembly tolerances need uniformity provided by electroless process).

Benefits of electroless nickel

- Unlimited throwing power

- Little or no excess deposit at high points

- Deposits of excellent physical and chemical properties

- Reduced hydrogen charging (hydrogen embrittlement)

- Ability to coat surfaces which would be difficult or impossible by electroplating

Specifications

| Specs |

Thickness |

Comments |

| MIL-C-26074E |

|

|

| Class I |

|

As coated, no subsequent heat treatment. A bake for hydrogen embrittlement relief is not considered a heat treatment. |

| Class 2 |

|

Steel and other base metals heat treatable to improve hardness. |

| Class 3 |

|

Aluminum and other base metals not heat treatable. |

| Class 4 |

|

Aluminum alloy, heat treatable, processed to improve adhesion of the nickel deposit. |

| Grade A |

0.0010" min. |

|

| Grade B |

0.0005" min. |

|

| Grade C |

0.0015" min. |

|

| Specs |

Thickness |

Comments |

| ASTM-B733-04 |

Range from 0.0002" - 0.0024" |

ASTM specification requires the purchaser to well define the "type," "class," "service condition," "composition," "test method," etc. on ordering documents. |

| Type I |

|

No requirement for Phosphorus |

| Type II |

|

1-3 percent Phosphorus. |

| Type III |

|

2-4 percent Phosphorus |

| Type IV |

|

5-9 percent Phosphorus |

| Type V |

|

10 percent and above Phosphorus |

| SC0 |

0.1µm |

Service condition 0. Defined as a minimum coating thickness to provide specific material properties and extend the life of a part or its function. Applications include requirements for diffusion barrier, undercoat, electrical conductivity and wear and corrosion protection in specialized environments. |

| SC1 |

5µm |

Light service. For extending the life of a part. Typical environments include light-load lubricated wear, indoor corrosion protection to prevent rusting, and for soldering and mild abrasive wear. |

| SC3 |

25µm |

Moderate service. Moderate environments such as non marine outdoor exposure, alkali salts at elevated temperature, and moderate wear. |

| SC4 |

75µm |

Severe service. Very aggressive environment. Typical environments would include acid solutions, elevated temperature and pressure, hydrogen sulfide and carbon dioxide oil service, high temperature chlodie systems, very severe wear, and marine immersion. |

| |

|

|

| Class 1 |

|

As deposited, no heat treatment. |

| Class 2 |

|

Heat treatment at 260-400°C to produce a minimum hardness of 850 HK100 |

| Class 3 |

|

Heat treatment at 120-130°C for 2-4 hours to improve coating adhesion on steel and to provide for hydrogen embrittlement relief |

| Class 4 |

|

Heat treatment at 120-130°C for at least 1 hour to increase adhesion of heat treatable aluminum alloys and carburized steel. |

| Class 5 |

|

Heat treatment at 140-150°C for at least 1 hour to improve coating adhesion for aluminum, non age-hardened aluminum alloys, copper, copper alloys and beryllium. |

| Class 6 |

|

Heat treatment at 300-320°C for at least 1 hour to improve coating adhesion for titanium alloys |