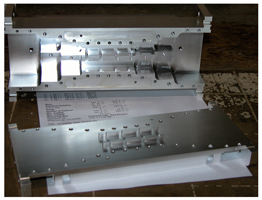

Services

Electro Loh provides a diverse range of plating and finishing services on nearly any metallic substrate. We offer finishes such as, black oxide, chemical film, nickel, gold, silver, passivation, tin, copper, zinc, and more. Electro Loh specializes in plating to thickness, using state of the art tools and micrometers; Electro Loh's services are guaranteed to fulfill even the most demanding applications, as well as being dedicated to providing the highest quality finishes available. This is what makes Electro Loh a leader of its industry.

Our Processes

RoHS Compliant Finishes

What is RoHS Compliance?

Mainly a european requirement, RoHS (Restriction of Use of Hazardous Substances) regulations limit or ban specific substances -- lead, cadmium, polybrominated biphenyl (PBB), mercury, hexavalent chromium, and polybrominated diphenyl ether (PBDE) flame retardants – in new electronic and electric equipment.

Black Oxide

Black oxide coating is produced by a chemical reaction between the iron on the surface of the ferrous metal and the oxidizing salts present in the black oxide solution.

More Info on Black Oxide process & specs

Chemical Film

Chemical Film is a widely used plating process for the protection of Aluminum. Applies only to Aluminum.

More Info on chemical film & specs

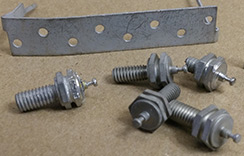

Copper

copper is commonly used as an underplating to enhance adhesion of deposits, improve electrical properties, impair migration of alloying elements into the final plated deposit or to improve corrosion resistance of the overall deposit.

More Info on copper plating & specs

Electroless nickel

The electroless process has several advantages over electroplating. Electroless process is the deposition of a metallic coating by a controlled chemical reduction that is catalyzed by the metal or alloy being deposited.

More info on electroless nickel, & specs

Gold

Gold plating it is an exceptional choice when electrical conductivity, solderability and corrosion resistance are necessary

More info on gold plating & specs

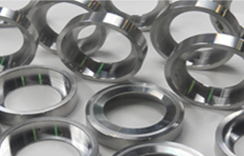

Nickel

Used in a variety of industries such as the electronics, electroforming, automotive markets, and many others. Nickel can be applied soft, hard, dull, or bright, depending on the application process used.

More Info on nickel plating & specs

Passivation Treatment

Designed to remove foreign metals from the surface of stainless and corrosion resistant steels and to promote natural tendency of surface to oxidize. Does not change the appearance of the base metal. Process purifies surface and therefore improves corrosion resistance.

More Info on passivation treatment & specs

Silver

Silver is one of the best electrical conductors. Has an excellent lubricity and smear characteristic for anti-galling uses on static seals, bushings, etc.

More Info on silver & specs

Tin

Tin has good conductivity, is corrosion resistant, while it helps improve solderability of substrates that are not otherwise easily soldered to. Tin is also considered non-toxic, non-carcinogenic, and is approved for food contact applications.

More Info on tin & specs

Zinc

Zinc coatings prevent oxidation of the protected metal by forming a barrier and by acting as a sacrificial anode if this barrier is damaged. The majority of hardware parts are zinc plated, rather than cadmium plated.

More Info on Zinc, & specs

Non RoHS Compliant Finishes

Cadmium

Cadmium plating provides excellent adhesion for paint, it is much more unsusceptible to stripping compared to zinc plating, for these reasons there is much more preference for cadmium plating over zinc in marine environments.

Lead

Lead is great for highly corrosive applications such as battery contacts, & strong mineral acids like sulphuric acid. Lead has good solderability making it ideal for use in critical electrical and electronic applications.

More Info on lead plating & Specs

Tin-Lead 60/40

Tin-lead alloys are the easiest alloys that can be electroplated. The electromotive potentials of each of the metals are almost the same, making co-deposition simple.

More Info on Tin-Lead 60/40 & SpecsNeed Help?

If you have questions or concerns please do not hesitate to contact us

tel: 514-631-3730

Or

Contact by email