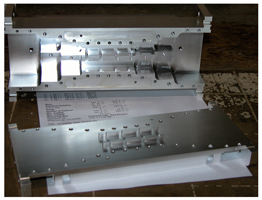

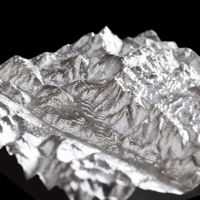

General Details and Specification of Silver Plating Finish

White matte to very bright in appearance. Good corrosion resistance, depending on base metal. Will tarnish easily. Hardness varies from about 90 Brinnell to about 135 Brinnell depending on process and plating conditions. Solderability is excellent, but decreases with age. Silver is one of the best electrical conductors. Has an excellent lubricity and smear characteristic for anti-galling uses on static seals, bushings, etc.

Benefits of silver plating

- Excellent lubricity

- Exceptional smear characteristic for anti-galling

- Enhances Protective Passive Film

- Best electrical and thermal conductivity of all metals

- Great optical reflectivity in the visible range

Specifications

| Specs |

Thickness |

Comments |

| QQ-S-365D |

0.00005" up to 0.003” |

Increasing use in both decorative and engineering fields, including electrical and electronic fields. |

| Type I |

|

Matte. |

| Type II |

|

Semi-bright. |

| Type III |

|

Bright. |

| Grade A |

|

With supplementary tarnish-resistant treatment. |

| Grade B |

|

Without supplementary tarnish-resistant treatment. |

| Specs |

Thickness |

Comments |

| ASTM B 700-08 |

|

This specification covers requirements for electrodeposited coatings of silver used for engineering purposes that may be mat, bright, or semi bright and are not less than 98% silver purity. |

| Grade A |

|

Mat |

| Grade B |

|

Bright |

| Grade C |

|

|

| Grade D |

|

Semi-bright |

| Class N |

|

A finish that has had no supplementary tarnish resistant treatment. |

| Class S |

|

A finish that has had a supplementary tarnish resistant treatment. |