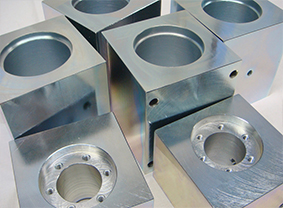

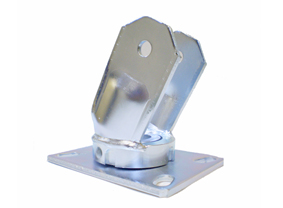

Zinc Plating

General Details and Specification of zinc palted Finishes

Either a bright or dull finish is acceptable. Bright zinc plating closely resembles bright chromium. Bright zinc does not have the permanence of surface appearance, however. Zinc coated steel will not rust even when exposed by scratches, because of the galvanic protection of the zinc. On weathering, zinc turns to a drab gray color. Zinc should be deposited directly on the base metal. (Nickel is a permissible undercoat if base metal is a corrosion resistant steel.) Parts having a hardness greater than Rc-40 must be given a heat treatment prior to plating. Springs having hardness over Rc-40 must be given an after plating baking at 375 + 25 F for 3 hours.

Benefits of zinc plating

- Zinc coatings are economical

- Continues to offer protection even if slightly damaged on the surface

- Excellent modern substitute for less environmentally friendly cadmium coatings

- Great ductility and adhesion

- Consistent distribution

- Suitable for either rack or barrel plating

Specifications

| Specs | Thickness | Comments |

|---|---|---|

| ASTM B 633-07 | No dimensional change | The primary use of chromate finishes on zinc is to retard or prevent formation of white corrosion products on zinc surfaces. |

| Fe / Zn25 SC4 (very severe) |

25µm(0.0010") |

|

| Fe/Zn 12 SC3 (severe) |

12µm (0.00050") | |

| Fe / Zn8 SC2 | 8µm (0.00032") | |

| Fe / Zn5 SCI (mild) |

5µm (0.00020") | |

| Type I | As plated without supplementary treatment. | |

| Type II | With colored chromate treatment. 96h Salt Spray |

|

| Type III | With colorless chromate treatment. 12h Salt Spray |

|

| Type V | With colorless passivate. 72h Salt Spray |

|

| Type VI | With colored passivate 120h Salt Spray |