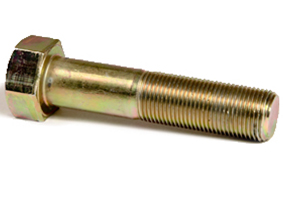

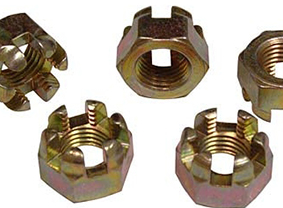

Cadmium Plating

General Details and Specification of cadmium Finish

Bright and silvery white in color, or supplementary treatments for type II can be golden, iridescent, amber, black, and olive drab. Corrosion resistance is very good, especially with type II finish. Type II shall show no surface corrosion products after 96 hours (5%) salt spray exposure. Parts with hardness grater than Rc-40 shall be stress-relieved before cleaning and plating. Parts subject to flexure (springs, etc.) Over Rc-40 hardness shall be given a 375 + 25 F post bake. Salt spray test: type II Class I Test period for White Corrosion products: 96 hours.

Benefits of cadmium plating

- Provides an excellent corrosion resistance even at relatively low thickness and in salt atmospheres.

- May be dyed to many colors such as blue, green, red, etc. in addition to standard clear, yellow, black, and Olive Drab.

- Has attractive final finish.

- Good lubricity and solder ability characteristics.

- An attractive final finish.

- A good paint base.

Specifications

| Specs | Thickness | Comments |

|---|---|---|

| QQ-P-416F | ||

| Type I | No supplementary treatment. | |

| Type II | Supplementary chrome treatment. |

|

| Type III | Supplementary phosphate treatment. |

|

| Class I | .0005" min. | |

| Class II | .0003" min | |

| Class III | . 0002" min. |