Chemical Film Coatings

General Details and Specification of chemical film finishes

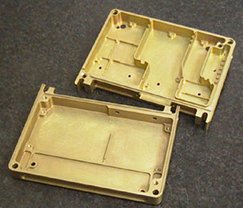

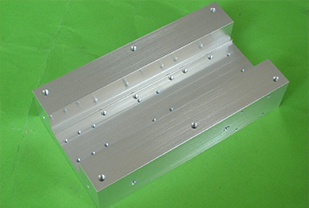

Chemical Film or Chromate Conversion is a widely used plating process for the protection of aluminum. Chemical Film is a chemical process that produces a protective chromate conversion film on aluminum and aluminum alloys. The coating can be applied on the aluminum surface, with or with out colour, to form a surface corrosion resistant film when it is dried.

Specification Range from. MIL-DTL-81706B, Class 1A, Form II, Method A,B,C; and under Class 3, form II, Method C. The clear Iridite 14-2 finish also qualifies under Class 3, Form II, Method C of the same specification. Qualifies under Specification MIL-C-5541E.

Colors can vary from colorless to golden—iridescent----brown. Materials should conform to MiL-C-81706. Coating shall be continuous, free from powdery areas, breaks, scratches, etc.

Benefits of chemical film finishes

- Conversion Coatings are Economical

- They are easy to use and offer a variety of valuable properties to extend the service life of parts

- Minimize Surface Oxidation of Aluminum Parts

- Very Thin Coating: No Dimensional Change

- Primer for Paint Adhesion and other topcoats

Specifications

| Specs | Thickness | Comments |

|---|---|---|

| DTL-5541F | No Dimensioanl Changes | |

| Class 1A | No Dimensioanl Changes | Class 1A is used as a corrosion preventative film (unpainted) or to improve adhesion of paint finish systems. |

| Class 3 | No Dimensioanl Changes | Class 3 is used as a corrosion preventative for electrical and electronic applications, where low resistance contacts are required. |

| Type I | No Dimensioanl Changes | Compositions containing Hexavalent Chromium. |

| Type II | No Dimensioanl Changes | Compositions containing no Hexavalent Chromium. |