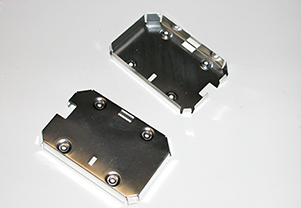

General Details and Specification of Tin Plated Finishes

Color is gray-while in a plated condition. Has a very high luster in fused conditions. Soft, but is very ductile. Corrosion resistance is good. (Coated items should meet 24-hour 5% salt spray requirement). Solderability is excellent. Tin is not good for low temperature applications.

Benefits of tin plating

- Excellent lubricity

- Exceptional smear characteristic for anti-galling

- Enhances Protective Passive Film

- Best electrical and thermal conductivity of all metals

- Great optical reflectivity in the visible range

Specifications

| Specs |

Thickness |

Comments |

| MIL-T-10727C |

As specified on drawing. Thickness guide (not part of spec.) as follows: |

|

| Type I |

|

Electrodeposited. Use ASTM-B-545 as a guideline. |

| .0001"-.00025" |

For contacts and bus bars. |

| .0002"-.0004" |

Flash for soldering. |

| .0003" min. |

To prevent galling and seizing. |

| .0002-.0006" |

Where corrosion resistance is important. |

| Specs |

Thickness |

Comments |

| ASTM B545-97 |

|

|

| Class A |

2.5µm (100µin) |

Mild service conditions, particularly where the significant surface is shielded from the atmosphere (as in electronic connector housings). To provide corrosion and tarnish resistance where greater thicknsesses may be detrimental to the mechanical operation of the product (for example, small electrical spring contacts and relays). Class A is often used for tin coatings that are not to be soldered, but must function as low-resistance electrical contact surfaces. |

| Class B |

5µm (200µin) |

Mild service conditions with less severe requirements than class C. Applications are as follows: precoating on solderable basis metals to facilitate the soldering of electrical components; as a surface preparation for protective painting; for antigalling purposes; and as a stopoff in nitriding. Also found on baking pans after reflow. |

| Class C |

8µm (320µin), (10µm (400µin) for steel substrates) |

Moderate exposure conditions, usually indoors, but more severe than Class B. Examples are electrical hardware (such as cases for relays and coils, transformer cans, screened cages, chassis, frames, and fittings) and for retention of the solderability of solderable articles during storage. |

| Class D |

15µm (600µin), (20µm (800µin) for steel substrates) |

Severe service, including exposure to dampness and mild corrosion from moderate industrial environments. Examples are fittings for gas meters, automotive accessories (such as air cleaners and oil filters), and in some electronic applications. |

| Class E |

30µm (0.0012 in): |

Very severe service conditions, including elevated temperatures, where underlying metal diffusion and intermetallic formation processes are accelerated. Thicknesses of 30 to125 µm (0.0012-0.005 in) may be required if the coating is subject to slowly corrosive liquids or corrosive atmospheres or gasses. Thicker coatings are used for water containers, threaded steel couplings of oil drilling strings, and seacoast atmospheres. |

| Class F |

1.5µm (60µin) |

Similar to Class A, but for shorter-term contact applications and short shelf-life requirements, subject to purchase approval. |

<

<